Why Us

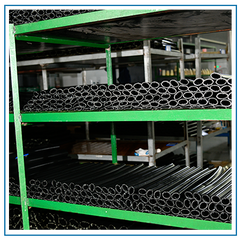

Wuhan Jackwin Industrial Co., Ltd. is a professional manufacturer that specializes in manufacturing,designing and distributing high performance silicone hoses,rubber hoses,filters,air cooler (CAC) hoses, filters.stainless steel T-bolt clamps,aluminum tubing,cold air intake kits,and radiator heater coolant hose kits for various engines in automotive, racing, motorcycle, marines, aerospace, industries, and agriculture. They are widely used to replace old rubber hoses or connect/replace current cooling, air, oil and fuel systems,electrical components, CNC machined products from aluminum or steel. They serve multiple functions as coolant hoses, radiator and heater hoses, turbocharger hoses, inlet hoses, breather hoses, vacuum hoses and etc.

![]()

Full Manufacturing Capacity

Our factory have more than 3000 SQM area in workshop covers 6 silicone hose production lines and 4 rubber hose production lines, enable us to produce around 80000 pcs hoses per month.

![]()

Our Products Standards

Our silicone hoses are compliant with the SAE J20 R1 Class A standard, and our heater hose meets the requirements of the SAE J20 R3 Class A standard. Our coolant silicone hoses meet or surpass the requirements of the SAE J20 R4 Class A standard. The fuel and oil fluorosilicone rubber hoses, also known as FKM or Viton hoses, comply with the SAE J30 standard. Our fire retardant silicone hose meets the specifications of UL94-V0. Lastly, the silicone hoses used in railway applications meet the requirements of the EN45545-2 standard.

![]()

Our Quality Control Systems

We strictly carry out below testing contents for silicone and rubber hoses.

-Aging test

-Coolant test

-Oil Immersion

-Burst Test

-Abrasion test

-Tensile test

-Radial Expansion

-Vacuum test

-Hardness test

-Tear test

![]()

![]()

Customized Silicone Rubber Hoses

We provide customized silicone hoses in various sizes and colors, including black, blue, red, green, pink, yellow, white, and more, according to customers' preferences. These hoses are of high quality, offering superior durability, flexibility, and resistance to common automotive fluids. They ensure long-lasting performance and minimize the risk of leaks or hose failure, meeting production standards. Our range of silicone hoses includes straight joiner couplers, reducer hoses, 90 degree elbows, 45 degree elbows, 135 degree elbows, 180 degree elbows, T-shape hoses, hump couplers with stainless steel rings, and vacuum silicone hoses. These hoses are reinforced with heat-resistant fibers or wire. Additionally, we offer OEM manufacturing and OBM branding options.

![]()

Silicone Hose Manufacturing Process Flow

Silicone Hose Production is very complicated and is specially produced hand-made, with 10 steps for the Silicone Hose Manufacturing Process Flow:

Silicone Material Mixing - Calendering - Fabric Cutting - Rolling & Forming - Heating & Vulcanization - Demoulding - Silicone Hose Cutting - LOGO Printing - Inspection - Packing

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

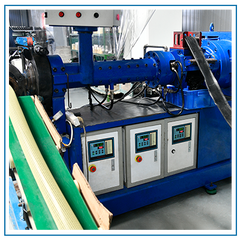

Rubber Hose Manufacturing Process Flow

Rubber material has several different types, according to its composition, it includes EPDM, nitrile SBR, NBR / HNBR, CR, AEM, neoprene, synthetic polyisoprene, PFM / FKM (Viton), and silicone.

Two types of rubber hose manufacturing process flow:

- Extrusion Rubber Hose Manufacturing Process Flow

Mixing - Reinforcement Textile Braid - Inner Rubber Hose Extrusion - Outer Rubber Hose Extrusion - Forming - Heating & Vulcanization - Hose Cutting - Printing - Cleaning - Inspection(Pressure Testing) - Packing

- Moulded Rubber Hose Manufacturing Process Flow

Mixing - Forming in Mould - Heating & Vulcanization - Printing - Cleaning - Inspection - Packing

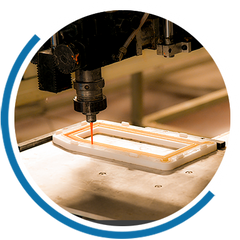

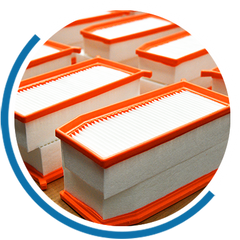

Filter Types

Automotive air filter is a filter media product for preventing engines from being damaged by dust, sand, dirt and others contaminants into the cabin.

Air Filter, Cabin Filter, Oil Filter, Fuel Filter, Truck Filter, HEPA Filter, Powercore Filter, High Flow Air Filter

Air Filter Production Process: Material Selection - Cutting and Shaping - Pleating - Frame Formation - Adhesive Application - Quality Control - Packaging